- Home Page

- Company Profile

-

Our Products

- Cable Tray

- Mild Steel Perforated Cable Tray

- Perforated GI Cable Tray

- Electrical Cable Tray

- Perforated Cable Tray

- Gi Raceway Cable Tray

- Powder Coated Perforated Cable Tray

- GI Perforated Cable Tray

- Stainless Steel Cable Trays

- Wire Mesh Cable Tray

- Stainless Steel Cable Tray

- GI Ladder Type Cable Tray

- FRP Cable Tray

- Light Pole

- CCTV Camera Pole

- Octagonal Pole

- Ladder Cable Tray

- GI Octagonal Pole

- MS Poles

- Flag Mast Pole

- GI Earthing Strip

- Cable Tray

- Contact Us

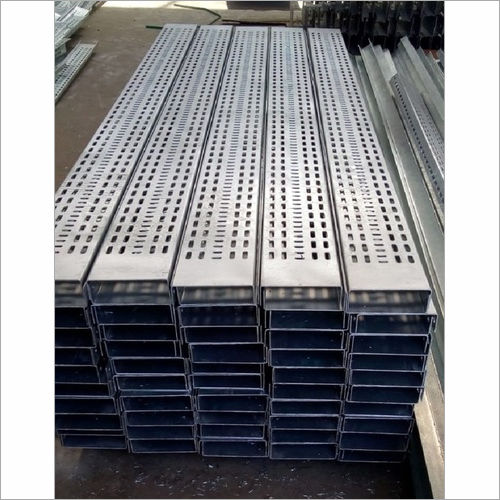

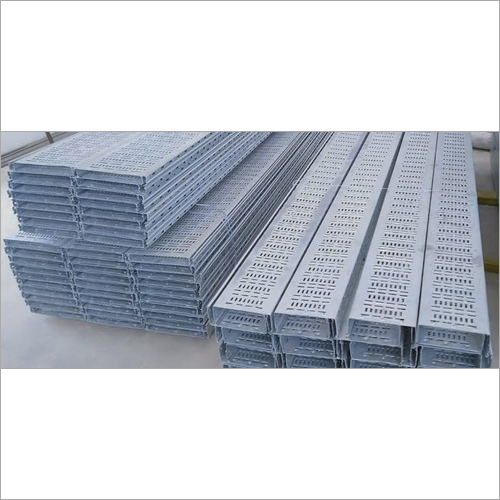

Perforated GI Cable Tray

250 INR/Meter

Product Details:

- Surface Finish HDG

- Product Type Perforated Through

- Material Steel

- Standard Thickness 1.2,1.6,2,2.5,3 Millimeter (mm)

- Length 2500 Millimeter (mm)

- Width 50-600 Millimeter (mm)

- Dimension (L*W*H) 2500*100*50 Millimeter (mm)

- Click to view more

X

Perforated GI Cable Tray Price And Quantity

- 250 INR/Meter

- 100 Meter, ,

Perforated GI Cable Tray Product Specifications

- 2500 Millimeter (mm)

- Steel

- 50-600 Millimeter (mm)

- HDG

- 2500*100*50 Millimeter (mm)

- Perforated Through

- 1.2,1.6,2,2.5,3 Millimeter (mm)

Perforated GI Cable Tray Trade Information

- Telegraphic Transfer (T/T)

- 500-1000 Meter, , Per Day

- 7-8 Days

- Free samples available with shipping and taxes paid by the buyer

- plastic Wrapping

- All India

- ISO 9001:2015, ISO 14001:2015

Product Description

Perforated GI cable tray is a sort of cable tray featured with holes on side rails and bottom sheet for laying power. This is also suited for the purpose of signaling in industrial plants, allocating electricity and few others. This is highly demanded for the gyms, hospitals, department stores, airports and other allied industries. This is a highly corrosion resistant as well as highly durable tray of low maintenance and space-savvy design. Perforated GI cable tray is accessible with superb chemical resistance and high tensile strength.

- Product Name:- Perforated Cable Tray

- Width:- 50-600 mm Height:- 25-100 mm

- Thickness:- 1.2,1.6,2,2.5,3 mm

- Material:- Hot Rolled , Cold Rolled Sheet

- Finishing:- Hot Dip Galvanized, Pre-Galvanized, Powder Coated

Product details :

| Country of Origin | Made in India |

| Tray Type | Perforated Cable Tray |

| Material | MS |

| Brand | Jetcotech Engineering |

| Color | For powder coated as per customer requirements |

| Surface Treatment | Hot-Dip Galvanized |

| Sheet Thickness | up to 2 mm |

| Side Rail Height | 35,50,80 |

| Shape | Rectangular |

| Surface Finishing | Hotdip GI, Pre-GI, Powder Coated, Stainless Steel 304,316 |

| Size | 100 mm to 600 mm width,35 50 and 80 mm Height and Customised |

| Cable Tray Coating | Hot-Dip Galvanized |

| Usage/Application | Outdoor, Indoor, Industrial, Commercial etc. |

Superior Corrosion Resistance

Our cable trays are coated with hot-dip galvanization, which significantly enhances their ability to withstand harsh environments. This surface treatment ensures long-lasting durability even in humid or industrial atmospheres, making them ideal for both indoor and outdoor applications.

Flexible Dimensions for Customized Solutions

Ranging from 50 mm to 600 mm in width and featuring a standard 2500 mm length, our perforated GI cable trays are adaptable for different project scales. Multiple thickness options (1.2, 1.6, 2, 2.5, and 3 mm) allow for optimal load bearing and installation flexibility.

Trusted Exporter and Manufacturer in India

With advanced manufacturing capabilities, we serve as a reliable supplier, exporter, and manufacturer of GI cable trays across India and international markets. Our commitment ensures consistent product quality meeting global standards.

FAQs of Perforated GI Cable Tray:

Q: How is the Perforated GI Cable Tray manufactured?

A: Our cable trays are manufactured using high-quality steel sheets that are perforated and formed to specified dimensions. The trays undergo a hot-dip galvanization (HDG) process, which coats them in a protective zinc layer to prevent corrosion.Q: What is the range of dimensions available for these cable trays?

A: The cable trays are available in widths from 50 mm to 600 mm and a standard length of 2500 mm. The height and thickness vary, with thickness options including 1.2, 1.6, 2, 2.5, and 3 mm to suit different cable loads and installation needs.Q: When should perforated GI cable trays be used over other types?

A: Perforated GI cable trays are ideal when ventilation is needed for cables, helping prevent overheating. They are especially suitable for scenarios requiring clear cable visibility and accessibility for maintenance in industrial or commercial settings.Q: Where can these cable trays be installed?

A: These trays are designed for installation in a wide range of environments, including factories, commercial buildings, and infrastructure projects. Thanks to their HDG finish, they perform reliably both indoors and outdoors, even in corrosive or humid conditions.Q: What is the process for hot-dip galvanization on these trays?

A: The steel trays are submerged in a bath of molten zinc during the hot-dip galvanization process. This creates a tightly bonded alloy coating that significantly enhances corrosion resistance and extends the products lifespan.Q: How are these cable trays used in cable management?

A: Cable trays provide structured support and separation for electrical and data cables, facilitating efficient organization. The perforated design allows for heat dissipation and easy fixing of cables at desired intervals.Q: What benefits do perforated GI cable trays offer to installation projects?

A: These trays simplify cable routing and maintenance, improve airflow around cables, and offer strong mechanical protection. The multiple thickness and width options make them suitable for varied project needs, while their robust construction and HDG finish deliver long-term reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email